An added value, representative of made in Italy .

Reca Plast pays great attention to the development of its own and commissioned products, from the design of the article to the structural analysis, in a process capable of optimizing production costs. The solutions offered by Reca Plast in fact reflect the design and modeling potential of its technical office, valid in the development of technical components, but also of everyday items: the attention to design has in fact led to the creation of a wide range of plastic household items .

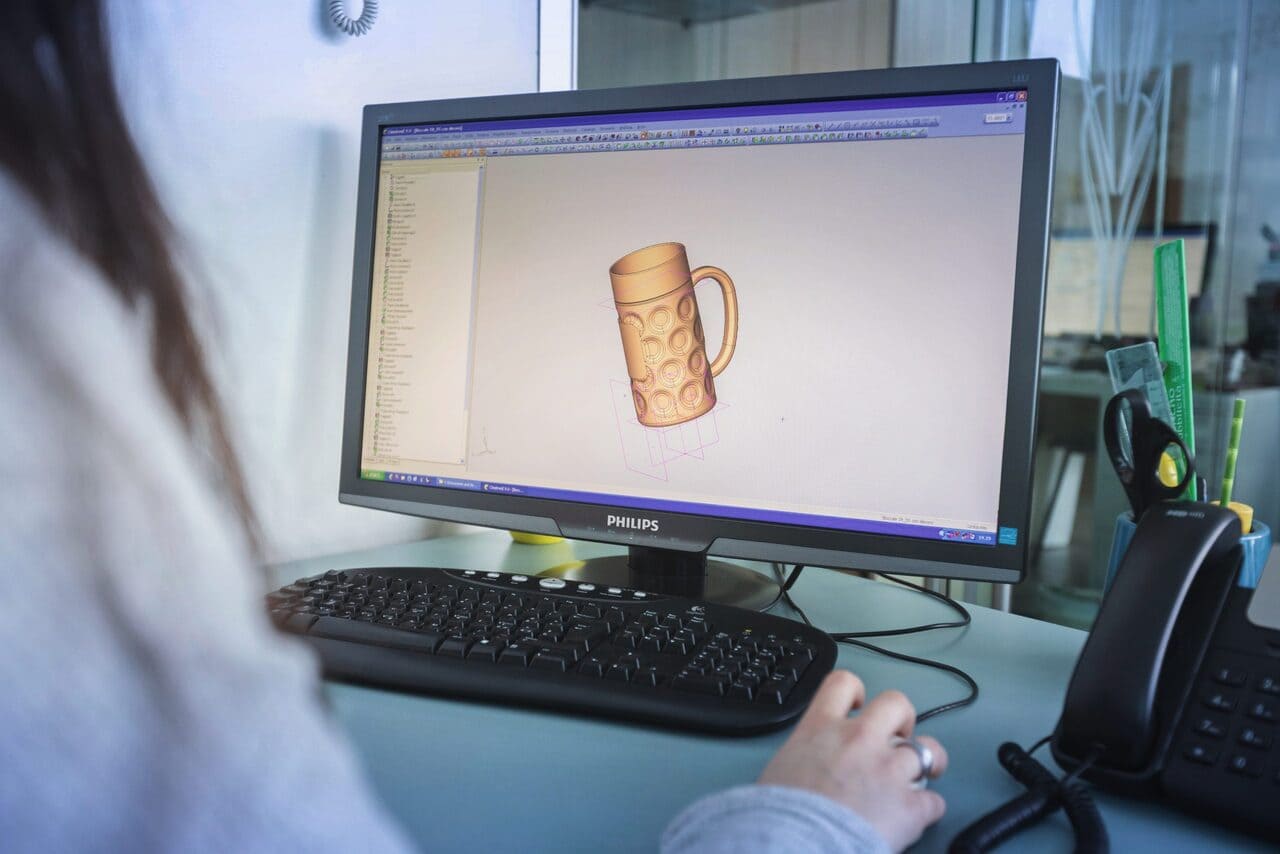

Qualified technicians work daily to provide effective solutions for the industrialization of any type of idea , through the use of advanced CAD-CAM software and rapid prototyping .

In the design phase of a new product, our team works alongside the customer supporting him from conceptual design to prototypes. Through the collection, analysis and synthesis of data, our designers can create any physical model, drawing manually and with computers. They are carried out in order to determine the distribution of internal forces and movements or tensions, deformations and displacements, the degree of resistance of the structure of the finished product. In this way, already in the design phase, all the problems relating to the engineering of the mold are solved.

Other services

Custom molds

Reca Plast's injection and extrusion mold construction department rests its solid foundations on the design and manufacturing experience of our technicians and employs technologically advanced machines.

Extrusion / blow molding

Blow molding is used for the production of hollow bodies, such as cans and bottles.

Injection molding

The materials mainly used are: polypropylene, TRITAN, ABS, thermoplastic rubber, nylon, polycarbonate, polyethylene, polystyrene, PMMA and SAN, also with self-extinguishing characteristics.

We are always available, get in touch with our department:

Sign up to our newsletter